the land of sludge, part 1

The rain continues, there is a new Pope, Vail Field is newly mowed, and we are barreling towards the end of the school year. A belated Happy Teacher Appreciation Week to the staff and teachers at WES who have seen me in my pajamas often and not said anything about it.

Good news!

Thanks to our Shared Energy Coordinator, Harry “Grants” Falconer, Woodstock was awarded a Municipal Planning Grant from the Vermont Department of Housing and Community Development for $18,756. This will be used to update our Town Plan, specifically our Future Land Use map. The Planning Commission will be taking on this work once they are done updating our Village zoning bylaws.

The artist known as MWWTP

Our main wastewater treatment plant on Maxham Meadow Way is due for renovation. This is for two reasons:

Like much of our infrastructure, the treatment plant has been a victim of underinvestment. The plant was built in 1967 and the last major upgrade was in 1982.

In order to meet our discharge permit, we need to update our filtration process, as the state regulates the levels of nitrogren and phosphorous we put into the Ottauquechee River.

Wastewater treatment in this plant starts by removing large debris and grit from the incoming water in the headworks building. The water is then pumped into two large tanks, where air is added to help break down waste. After that, the water flows into two settling tanks that separate out solids. Next, it passes through two chambers where it's disinfected with chlorine, then treated to remove the chlorine. The cleaned water is measured and then released into the Ottauquechee River. Solids are collected in two holding tanks and later removed by a contractor for disposal. Historically, the solids, or dewatered sludge, were spread on local farms. Currently, there is one contractor in the region who will haul away the sludge.

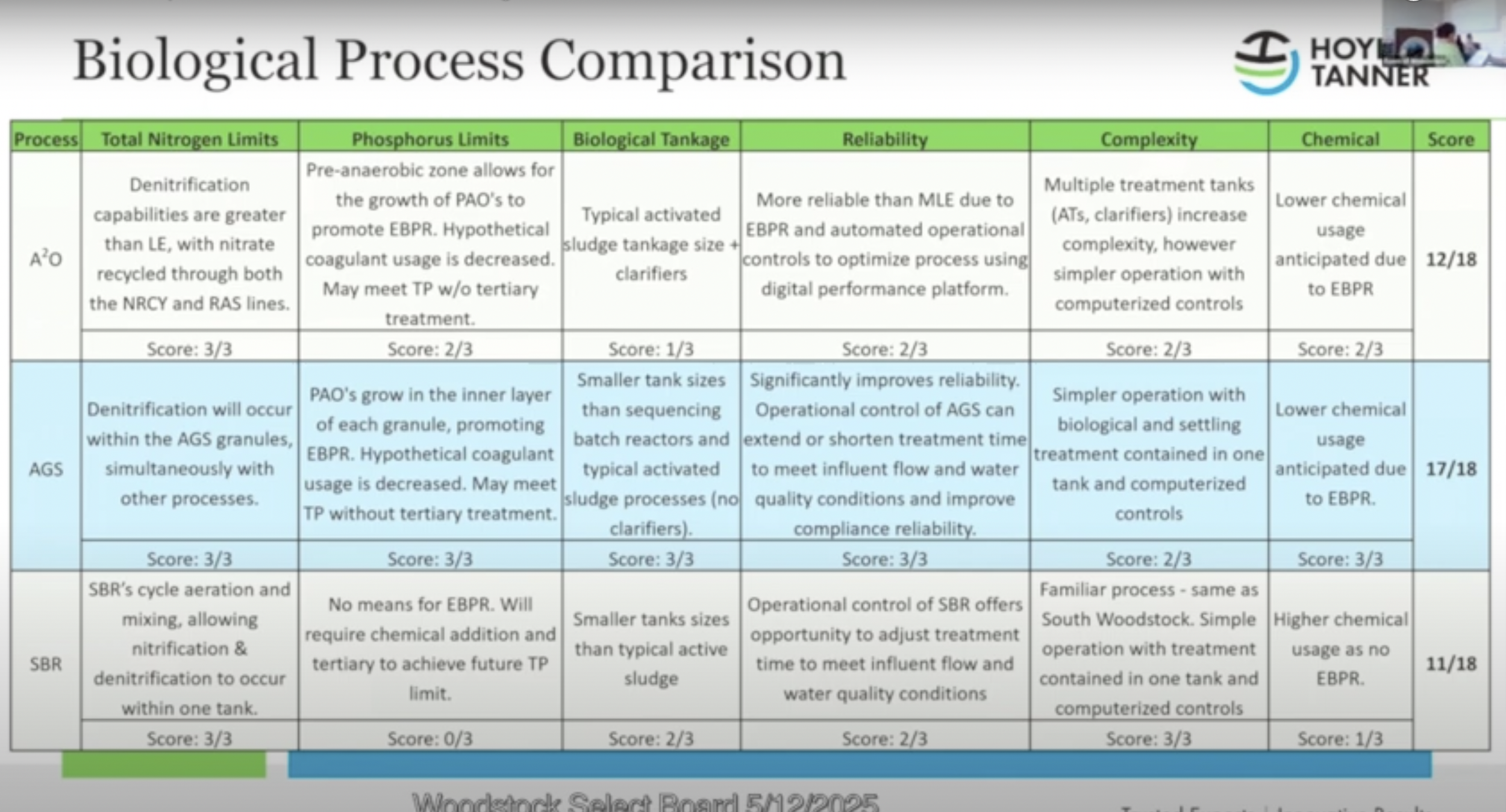

In December, the Selectboard asked the engineering firm Hoyle Tanner to investigate biological process alternatives that could be incorporated into the new plant design to increase efficiency and reduce both operational and construction costs. These processes include:

1. Anarobic/Anoxic/Oxic (A2O)

2. Aerobic Granular Sludge (AGS)

3. Sequencing Batch Reactor (SBRs)

Each of these processes has pros and cons, and you can watch the detailed presentation Hoyle Tanner gave the board last week, or just skim the comparison chart below. The next step is for the Selectboard to decide which process to move forward with.

Before the meeting adjourned, our lead operator Tim Lyons made a plea to the board: “This can has been kicked down the road as long as I’ve been here… the longer we wait, we know the more it’s going to cost. Nobody and no board has wanted to do this, and we’re getting to the point where the State is going to step in and put us on a compliance schedule.”

Reading/watching:

Can luxury housing do anything for homelessness? (this link was broken last time, apologies!)

Greensboro voters reject affordable housing project the saga continues in Greensboro

Arts education produces creative leaders from Woodstock’s very own Elizabeth Frascoia

Savannah Bananas on 60 Minutes - Baseball I can get behind

Question for the readers

When was the last time you felt connected to our community?